Walk-In or Reach-In Constant Climate Chambers? Find the Best Solution for Your Application

Walk-in chambers (WICs) and reach-in chambers (RICs) are like two sides of a coin. Both have distinctive benefits depending on your requirements.

The new line of BINDER™ standard WICs for pharma, food & beverage, and cosmetics applications are a valuable addition to the comprehensive range of BINDER™ RICs. Climate conditions in BINDER™ WICs are maintained over a wide temperature range, from 10°C to 50°C, and a relative humidity (RH) range of 20 percent to 90 percent. Temperature uniformity in one of our 6m³, 9m³ or 12m³ WICs is excellent, with values of only ±1.5K.

So when should you choose a BINDER™ RIC and when a BINDER™ WIC? Which factors, aside from chamber size, influence this decision? For example, what role do installation requirements play and what possibilities are available when configuring an individual solution? The following eight points should be considered when making a decision:

What Do WICs and RICs Have in Common?

Both types of BINDER™ chamber are designed and engineered to provide excellent constant climate conditions for long-term and accelerated stability testing in accordance with Guidelines [ICH Q1A (R2), VICH GL3, and WHO Climate Zones I to IVb, as well as shelf-life studies and storage conditions]. Both have an interior lining of 100 percent grade 1.4301 stainless steel and both offer qualification documentation including installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ).

What Are the Key Differences?

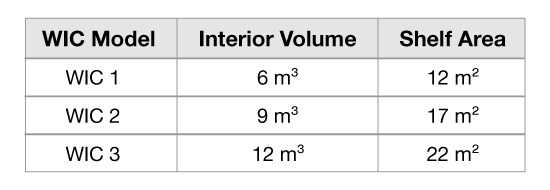

The most evident differences are the dimensions and the resulting shelf capacity of each chamber type. BINDER™ offers three standard WIC sizes, with interior volumes of 6m³, 9m³, and 12m³ respectively. The largest BINDER™ RIC, the KBF-S 1020, has an interior volume of approximately 1m³.

How Much More Shelf Area Does a BINDER™ WIC Provide Compared to a KBF-S 1020 RIC?

One standard KBF-S 1020 RIC, equipped with two stainless-steel shelves, provides 1.3m² of shelf area. The equivalent shelf area for all three WIC models is given in Table 1.

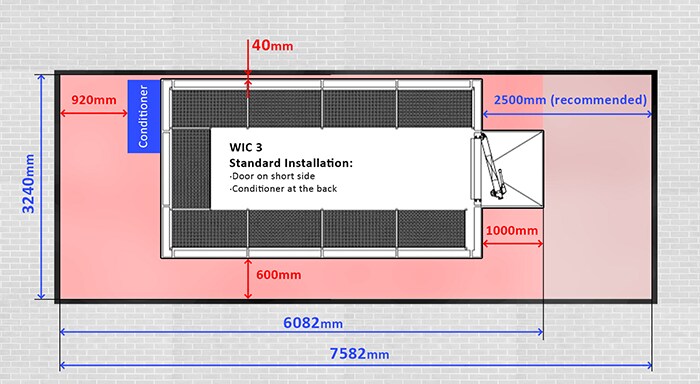

However, rather than comparing single units, it is necessary to consider how many RICs would theoretically fit in the set-up space of a single WIC. A typical WIC floor plan is shown in Figure 1, where the area in red denotes the total set-up space required (defined as the sum of the footprint of the chamber + the distances from the walls + the maintenance space).

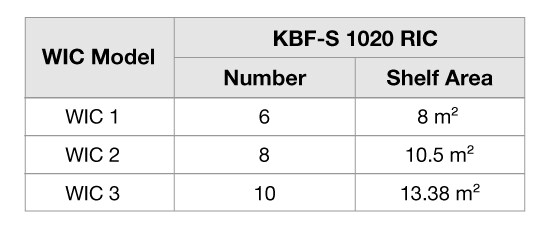

Given the set-up space, a WIC provides a factor of roughly 1.5-times to 1.6-times more shelf area in m² than the theoretical maximum number of RICs in the same set-up area (Table 2).

Why Does a WIC Require So Much Additional Space?

Each BINDER™ WIC has an external conditioner that is responsible for creating the climate conditions (heating/cooling + humidification/dehumidification + ventilation). If the conditioner is mounted to the back of the chamber, a maintenance aisle at least 500mm wide is mandatory such that service engineers can reach/access and service it. This requires more space, however, to save on this 'maintenance space' the conditioner can also be positioned next to the door for immediate access and service. Notably, conditioners are serviced from outside of the WIC so that climate conditions inside are not disturbed.

How Uniform Is the Temperature in BINDER™ WICs?

Temperature uniformity in BINDER™ WICs is excellent, with a tolerance of only ±1.5K. It should be noted, however, that since the KBF-S 1020 RIC has only one sixth to one twelfth of the respective interior volume of a WIC it naturally provides more uniform conditions (tolerance: ±0.3K).

How Can You Configure BINDER™ WICs?

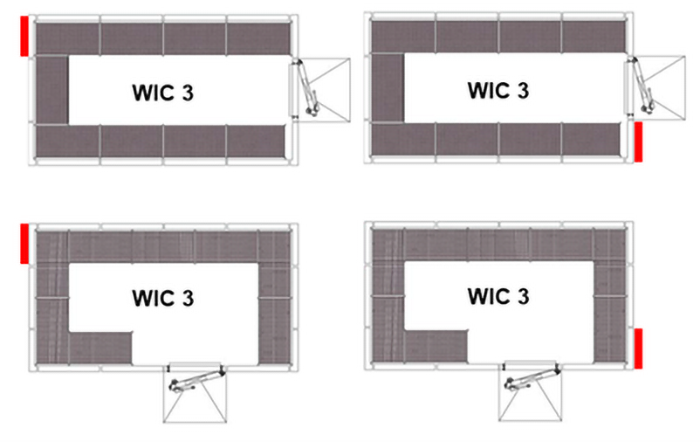

BINDER™ WICs offer a choice of two positions for the conditioners and two for the doors for maximum configurability in any given space. Example layouts for the Model WIC 3 chamber are given in Figure 2.

Standard features of a WIC include:

- A stainless-steel trolley ramp

- An emergency off (EMO) switch

- An LED working light with motion detection

- A lockable door with a 370mm × 370mm window

- A 3-year warranty

What Else Should Be Considered?

Given the set-up space required, it should be noted that one WIC provides a lot of shelf area but that it only does so under one climate condition. In comparison, six, eight or 10 KBF-S 1020 RICs offer the flexibility of six, eight or 10 different climates. The suitability of each solution will naturally depend on your test requirements. Another important consideration is the ease with which chamber components may be brought to the set-up space. These components are delivered on a pallet and clarification on building specifics such as the planarity/flatness of the set-up floor, the dimensions of doors/elevators, and the positions of the power, water, and drainage systems may be required. These considerations will be less extensive for a smaller RIC unit that is moveable on castors.

How Often Should Maintenance Be Conducted?

WICs use tap water for humidification and the tap water container should be rinsed regularly to avoid the build up of deposits. To ensure reliable and continuous operation, general maintenance is recommended once a year. The KBF-S 1020 RIC uses fresh water with a conductivity of 1µS/cm to a maximum of 20µS/cm, frequently requiring a water purification system.

Conclusions

Both WICs and the KBF-S 1020 RIC have their pros and cons. The choice between the two depends on your specific test requirements and your lab/facility requirements. It is important to consider factors such as space availability, sample volume requirements, water management, and any long-term plans carefully before making a decision.

Content provided by: